OvoSelect DX300 – Fully Automatic Egg Sorting and Violating System

Brochure Download Brochure

OvoSelect DX300 is a new model Fully Automatic Egg Grading and Violeting system with medium capacity.

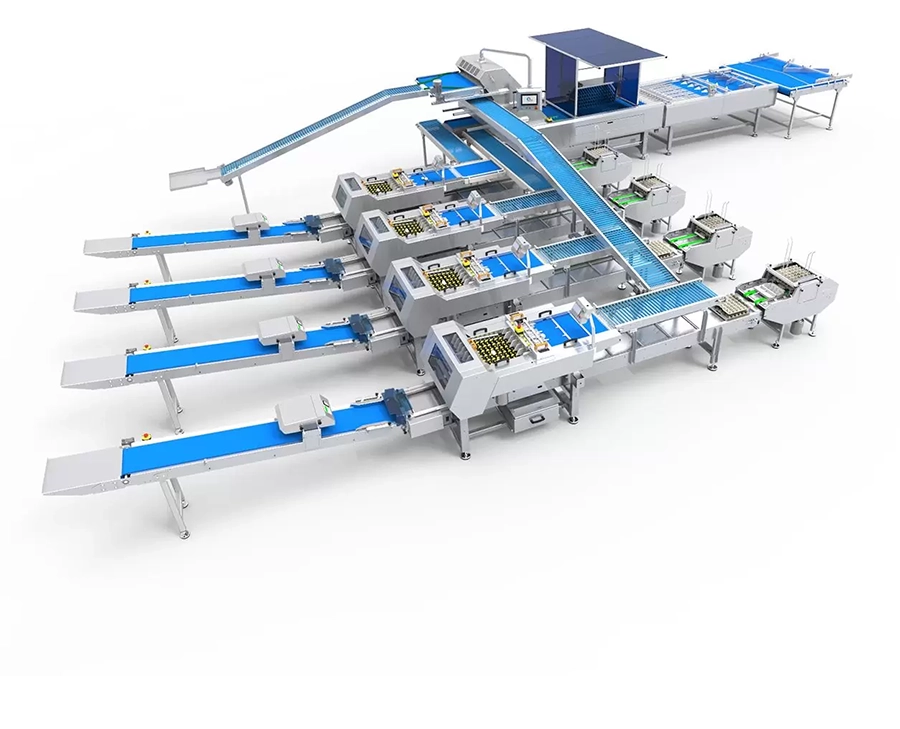

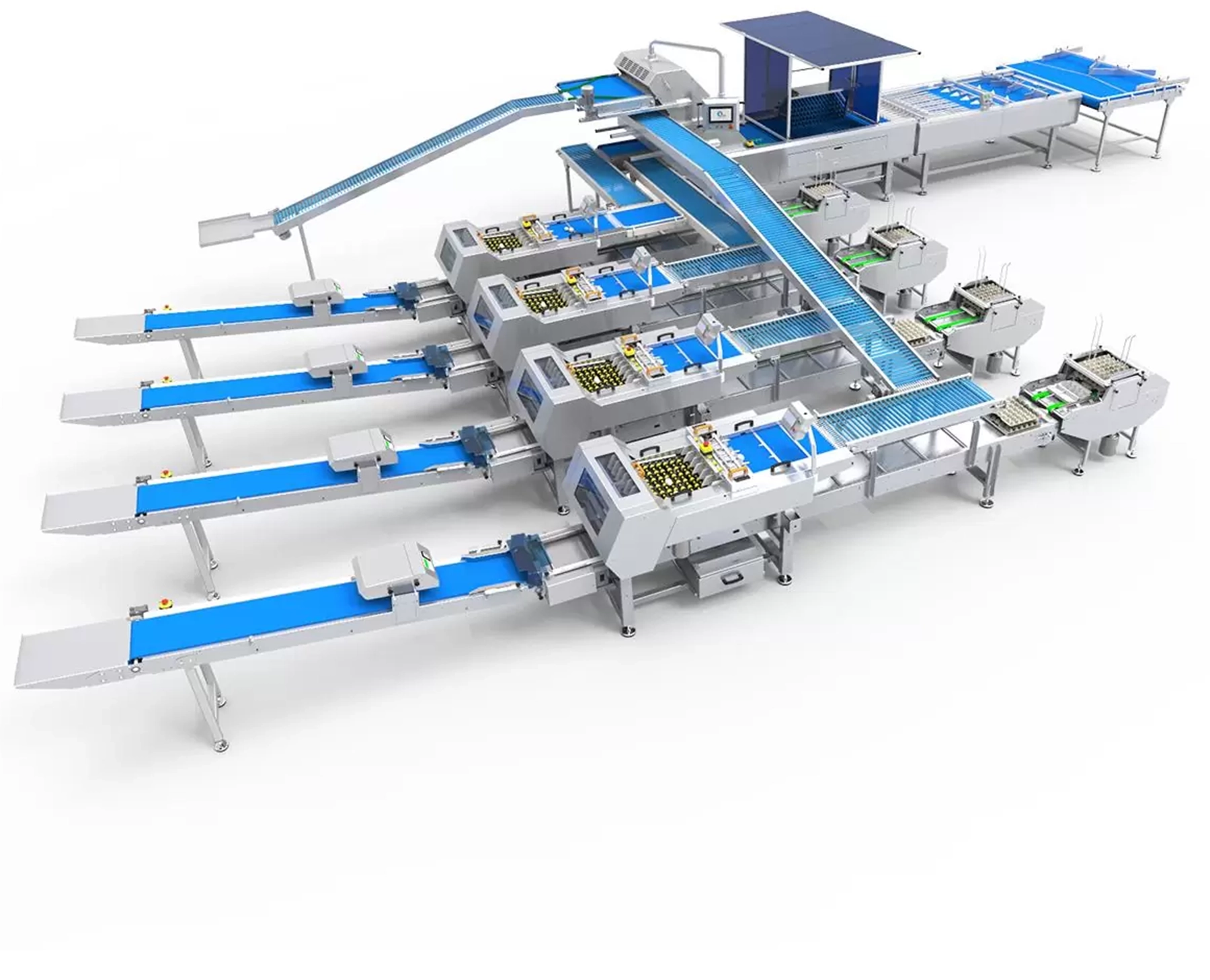

Automatic violating machine can be connected to maximum 4 outputs.

It sorts eggs according to maximum 7 different weight groups. It provides automatic filling of maximum 4 different grading groups selected according to preference into viols.

In the system with 4 automatic violating machines connected, the lowest quantity, maximum 3 different grading groups are directed to manual collection trays for manual violating.

It is designed for the installation of single-head printers. In this way, all eggs entering the sorting machine are weighed, coded according to their weight class or the exit to which they will be directed and made ready for shipment.

DX300 has a single-row egg transportation chain with speed and acceleration control in the tunnel. Thanks to the specially designed egg transportation trolleys, even the most sensitive eggs are transported without breaking as they are not exposed to any holding and squeezing force.

OvoSelect DX300 is designed in stainless chrome steel, washable structure.

It offers a visual and easy operation with its 7″ Color LCD touch screen.

OvoSelect DX300 has 6 egg transportation reels.

Main features of the Ovoselect DX300;

-

- Modular design, removable parts

- Egg entry bands are easily separated and cleaned

- All stainless chrome steel

- High quality electronic weighing system

- Low maintenance cost

- Ease of use

- Fast and quality after-sales service

- Manual or Automatic line options

- Broken Egg control section, Dark room

- Storing daily analyzes in memory after sorting

Printer Assembly

Designed for the installation of egg grading machines.

Egg collection table

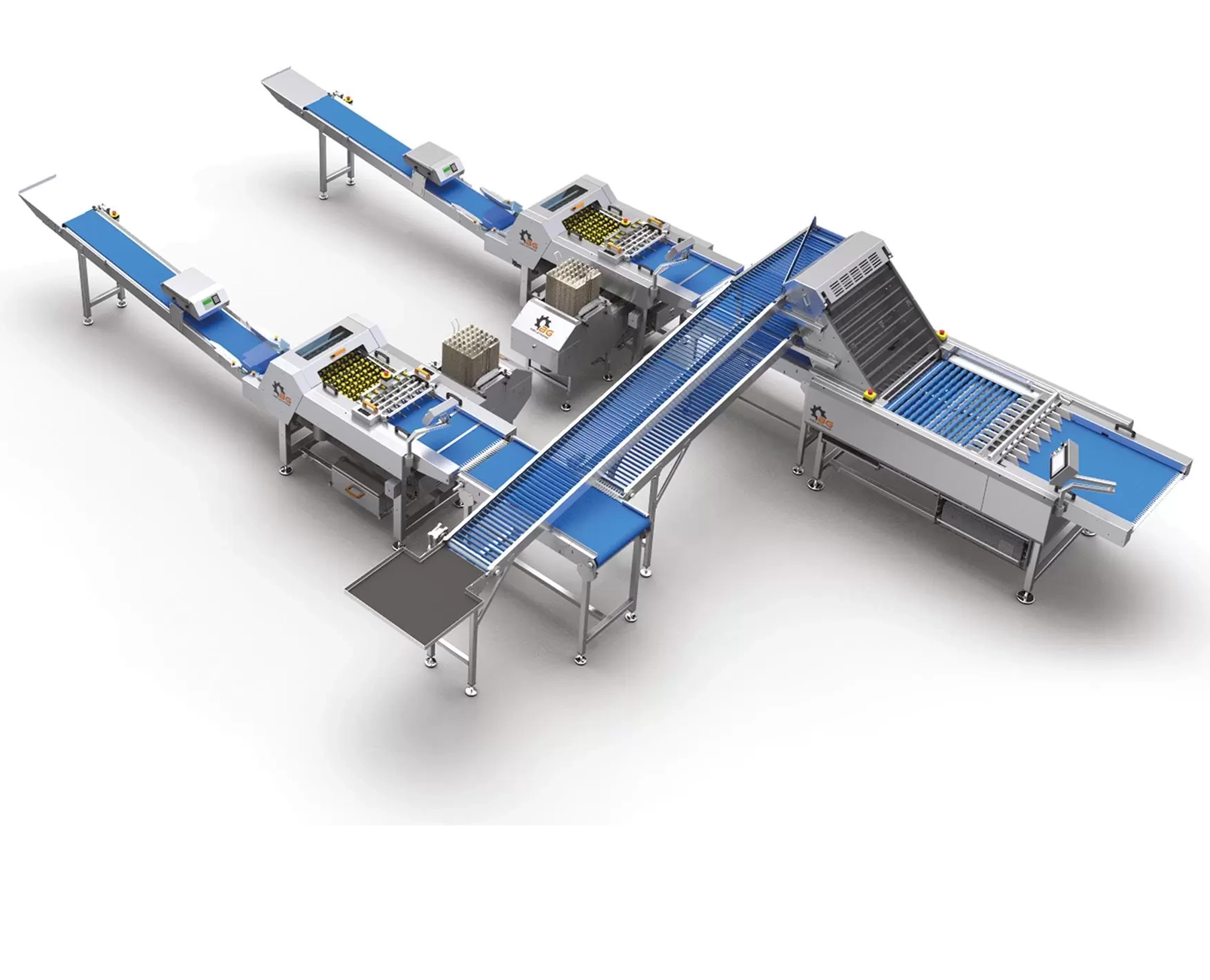

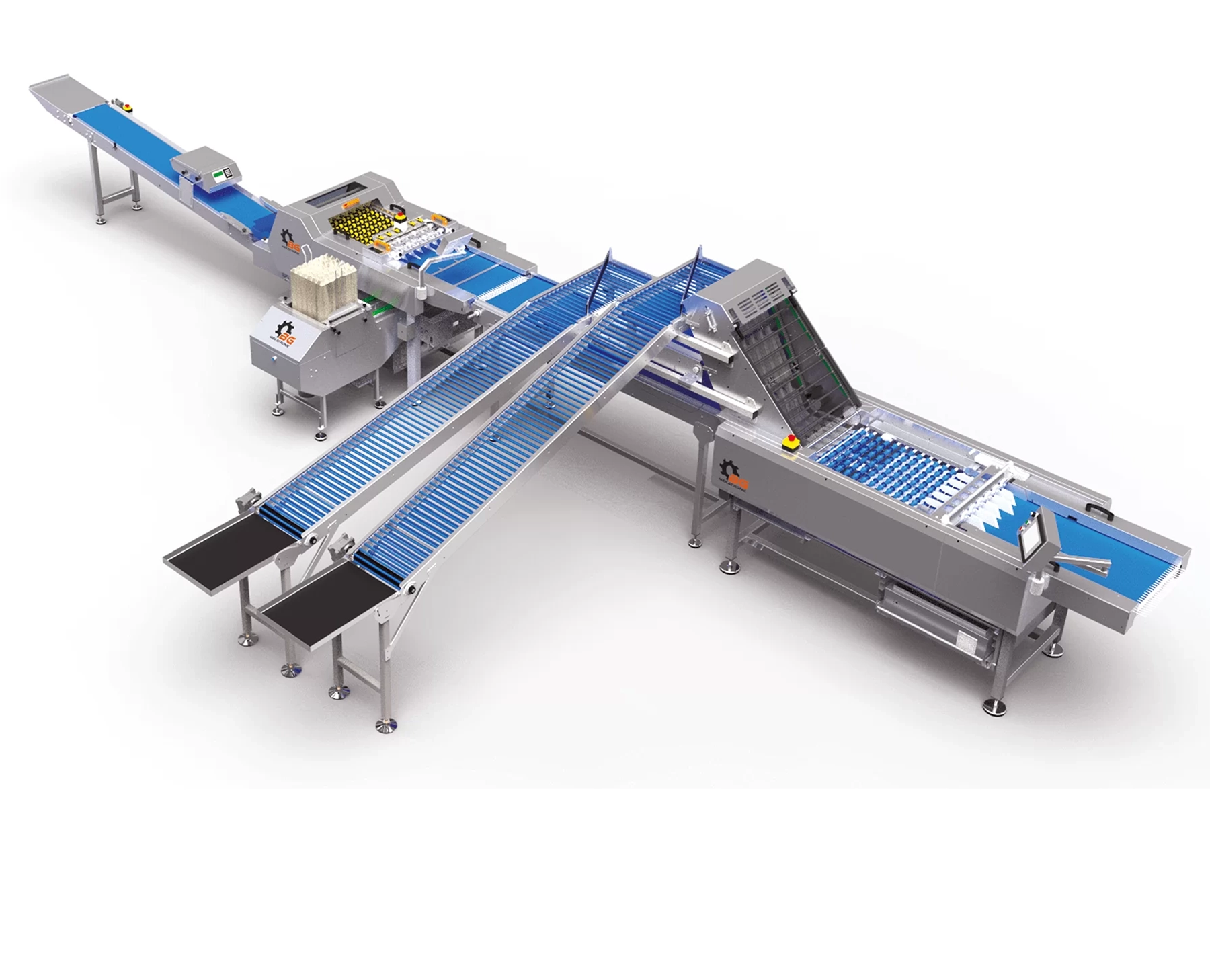

An optional number (1-3) of manual collection tables can be installed in the output lines of the DX300. On the tables, the eggs are transported to the operator with an antibacterial modular belt. The manual collection tables have an empty viola shelf.

Easily connected to the poultry egg line

The feeding belt of the Dx300 is designed to allow the entry of eggs from three sides. Thanks to the density sensing feature, the eggs are transferred without piling up and breaking.

Antibacterial Cleanable Reels

The egg transport reels used in Dx300 are made of anti-bacterial material. In this way, it is easy to clean as well as the desired flexibility and durability.

Cracked Egg Control Zone

The Dx300 uses a dark room with bottom illumination to easily identify cracked eggs on the egg conveyor.

Egg Transport Chain and Trolleys

The Dx300 has a single-row egg transport chain with speed and acceleration control. Thanks to the specially designed egg carts, even the most delicate eggs are transported without breaking as they are not subjected to any holding and squeezing force.

Technical Specifications

| Capacity: | 30,000 eggs/hour |

| Number of Input Lines: | 6 line input |

| Weighing System: | Electronic weighing |

| Weighing Accuracy: | 0,1 gram |

| Number of classifications: | 6 or 7 sizes |

| Operation: | Easy operation with 7″LCD display |

| Analysis: | Egg counts and average weight |

| Power consumption: | 2.0 kW + (4×1.2 kW) = 6.8 kWh, 380VAC (with 4 auto-collections) |

| Weight(Net/Gross): | 3.080 kg./ 3.280 kg. |

DX300 Layout and dimensions