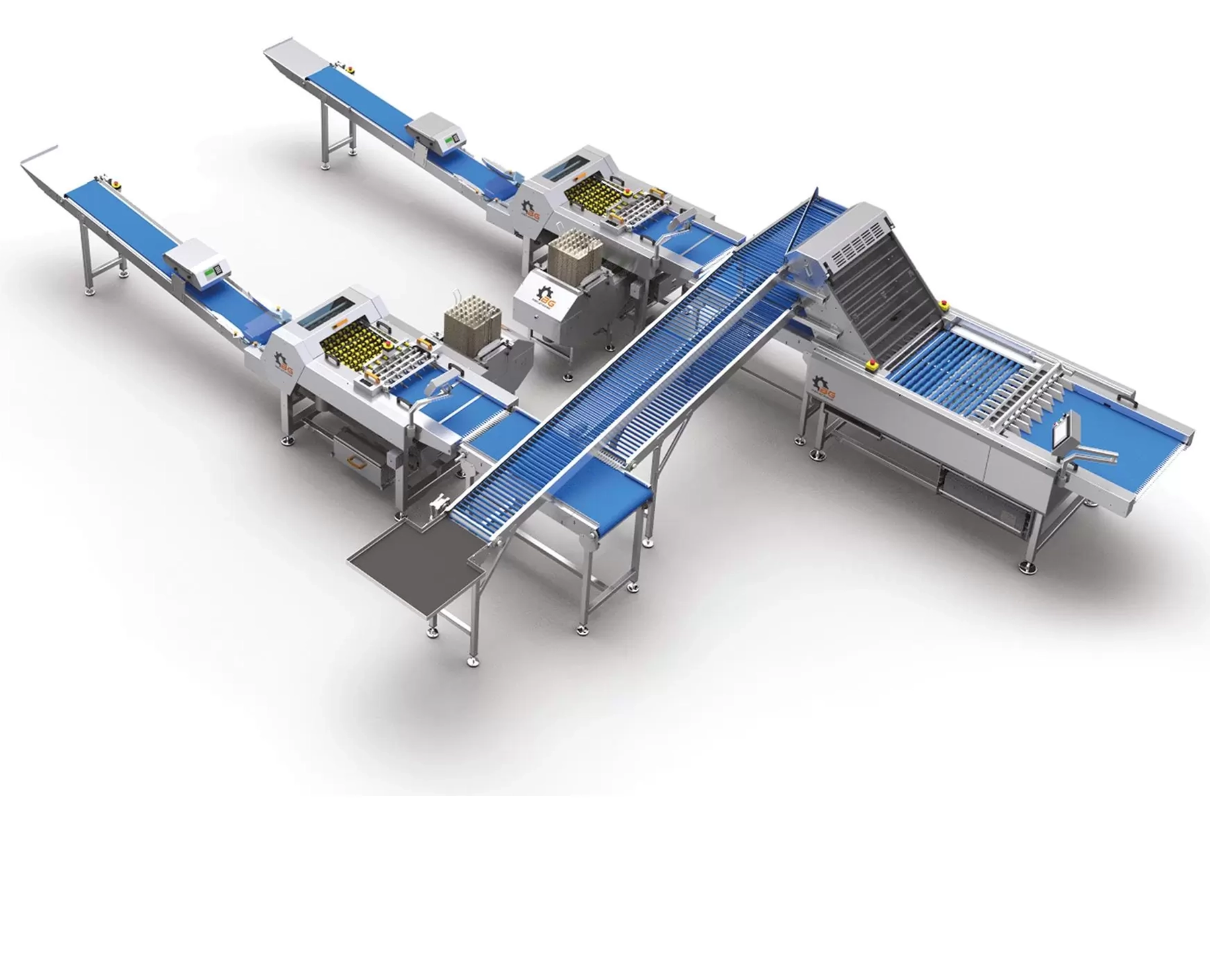

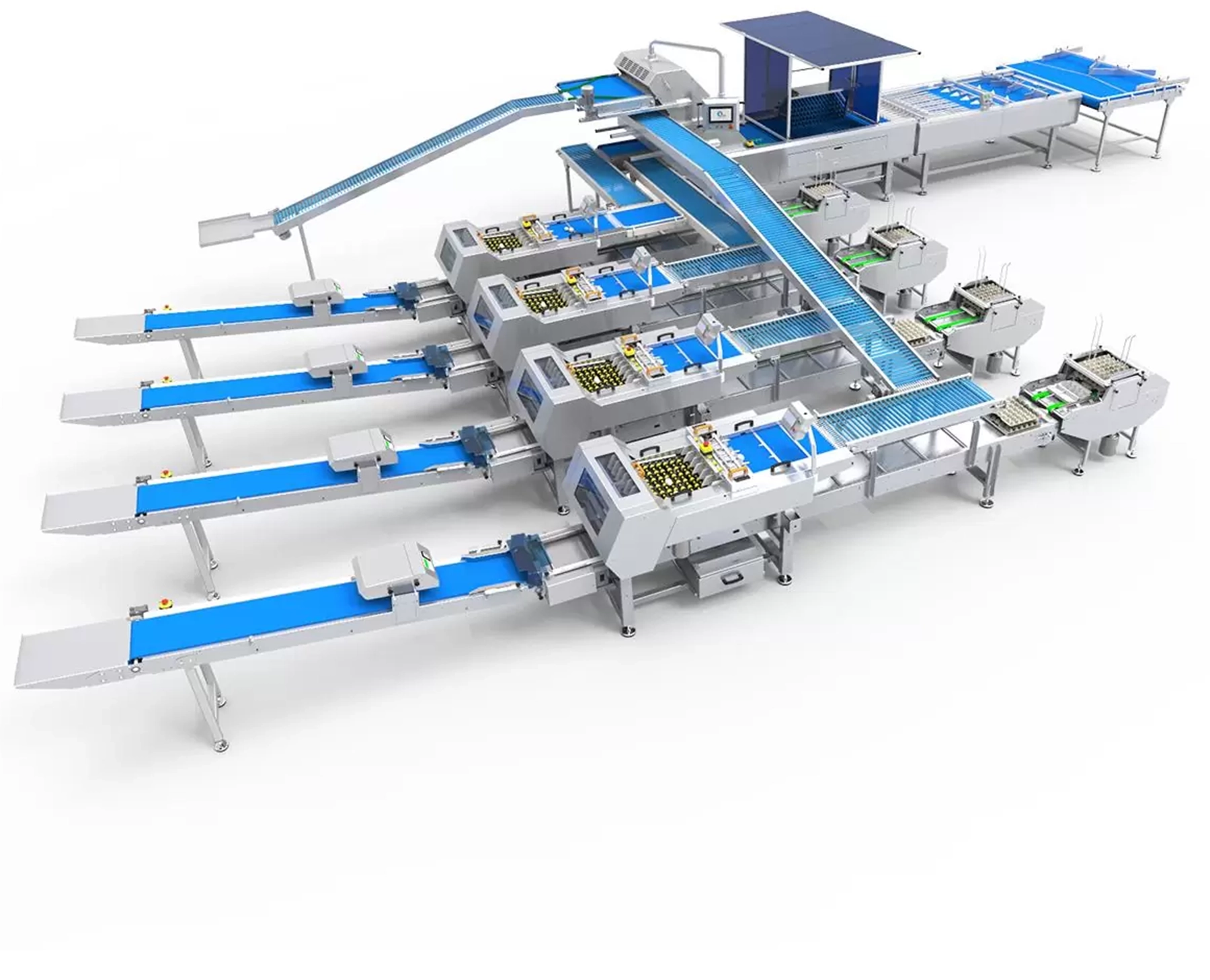

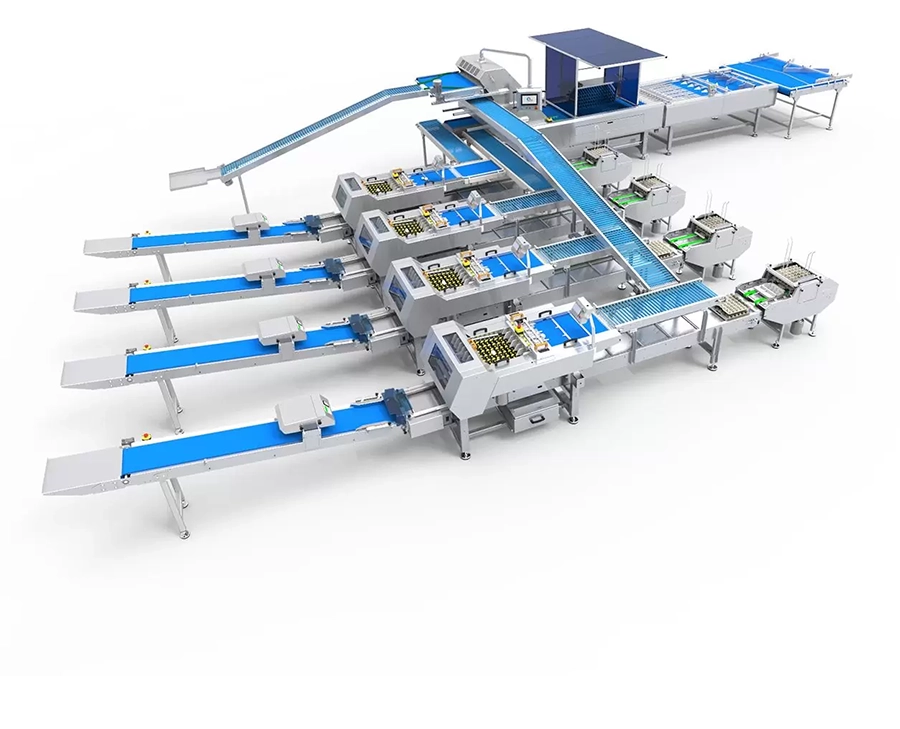

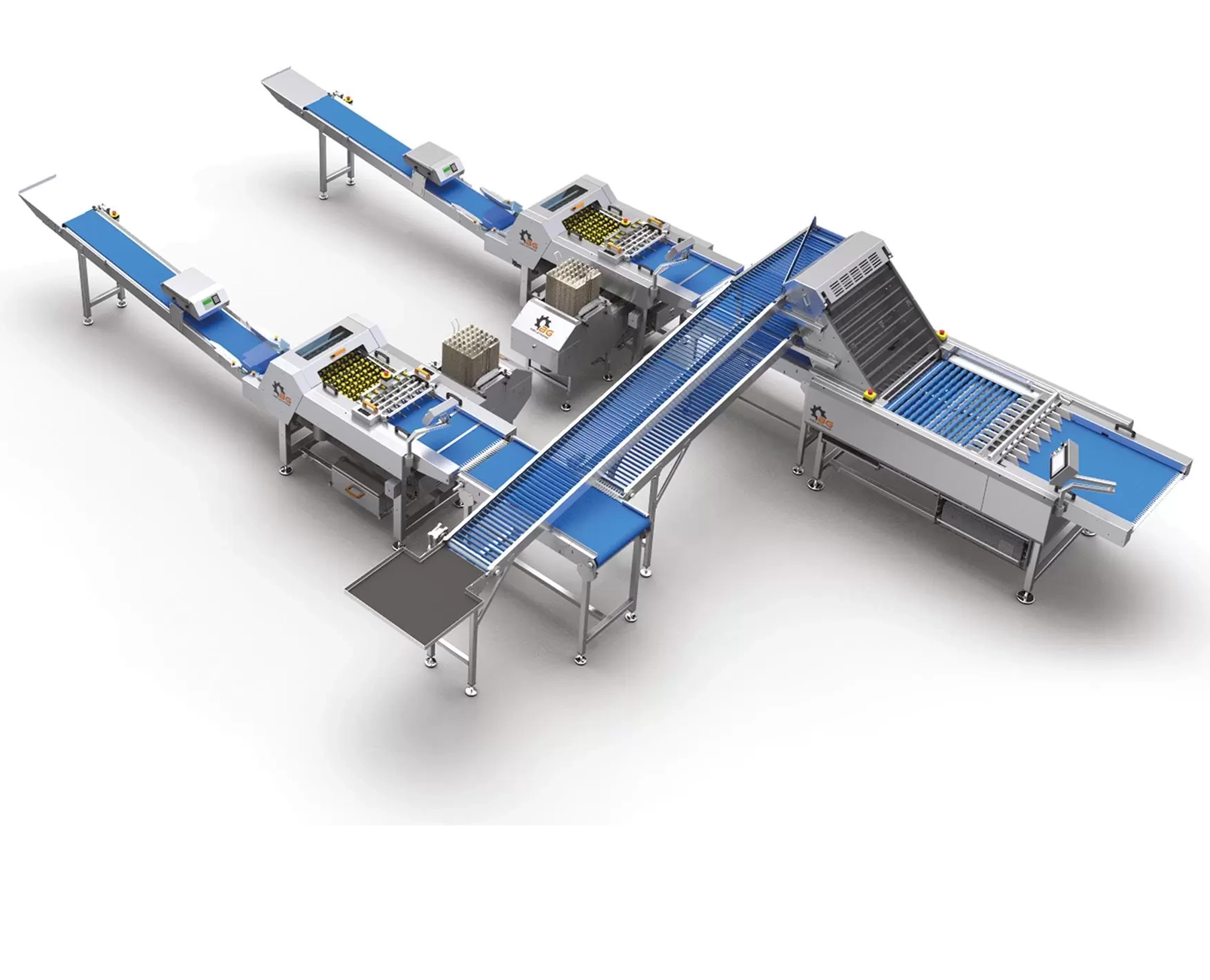

OvoSelect DX600 – Tam Otomatik Yumurta Tasnifleme ve Violleme Sistemi

Broşür Broşür İndir

OvoSelect DX600, orta kapasiteye sahip yeni model Tam Otomatik Yumurta Tasnifleme ve Viyolleme sistemidir.

Maksimum 6 çıkışa otomatik violleme makinası bağlanabilir.

Yumurtaları maksimum 7 farklı ağırlık grubuna göre tasnifler. Tercihe göre seçilen maksimum 6 ayrı tasnif grubunun viollere otomatik dolumunu sağlar.

5 adet otomatik violleme makinası bağlı olan sistemde miktarı en düşük olan, maksimum 2 ayrı tasnif grubu ise manuel olarak viollenmek üzere manuel toplama tepsilerine yönlendirilir.

Tek kafalı 2 adet yazıcının montajına uygun olarak tasarlanmıştır. Bu sayede tasnif makinasına giren tüm yumurtalar tartıldıktan sonra ağırlık sınıfına veya yönlendirileceği çıkışa göre kodlanarak sevkiyata hazır hale getirilir.

DX600 de, tünel içerisinde hız ve ivme kontrollü çift sıra yumurta taşıma zinciri bulunur. Özel tasarım yumurta taşıma arabaları sayesinde en hassas yumurtalar bile herhangi bir tutma- sıkma kuvvetine maruz kalmadığı için kırılmadan taşınır.

OvoSelect DX600 Paslanmaz krom çelikten, yıkanabilir yapıda tasarlanmıştır.

15″ Renkli LCD dokunmatik ekranı ile görsel ve kolay bir kullanım sunar.

OvoSelect DX600 de 12 sıra yumurta taşıma makarası bulunmaktadır.

Ovoselect DX600 ün başlıca özellikleri;

-

- Modüler tasarım, çıkarılabilir parçalar

- Yumurta giriş bantları kolayca ayrılıp temizlenir

- Tamamı paslanmaz krom çelik

- Yüksek kaliteli elektronik tartım sistemi

- Düşük bakım maliyeti

- Kullanım kolaylığı

- Satış sonrası hızlı ve kaliteli servis

- Manuel veya Otomatik hat seçenekleri

- Kırık Yumurta kontrol bölümü, Karanlık oda

- Tasnif sonrası günlük analizlerin hafızada depolanması

Yazıcı Montajı

2 adet tek kafalı yazıcı montajına uygundur.

Yumurta toplama masası

DX600’ün çıkış hatlarında isteğe bağlı sayıda (1-6) manuel toplama masası kurulabilmektedir. Masalarda yumurtalar anti bakteriyel modüler bant ile operatöre taşınır. Manuel toplama masalarında boş viyol rafı mevcuttur.

Kümes yumurta hattına kolayca bağlanır

DX600 ün besleme bandı üç taraftan yumurtaların girişine imkan sağlayacak şekilde tasarlanmıştır. Yoğunluk algılama özelliği sayesinde yumurtaların yığılmadan ve kırılmadan aktarımı yapılır.

Antibakteriyel Temizlenebilir Makaralar

Dx600 de kullanılan yumurta taşıma makaraları anti bakteriyel malzemeden üretilmiştir. Bu sayede istenilen esneklik ve sağlamlığın yanı sıra kolay temizlenebilir niteliktedir.

Çatlak Yumurta Kontrol Bölgesi

Dx600 de kullanılan alttan aydınlatmalı karanlık oda sayesinde yumurta konveyöründeki çatlak yumurtalar kolayca seçilebilmektedir.

Yumurta Taşıma Zinciri ve Taşıyıcı Arabalar

Dx600 de hız ve ivme kontrollü iki sıra yumurta taşıma zinciri bulunur. Özel tasarım yumurta taşıma arabaları sayesinde en hassas yumurtalar bile herhangi bir tutma- sıkma kuvvetine maruz kalmadığı için kırılmadan taşınır.

Teknik Özellikler

| Kapasite: | 60.000 yumurta/saat |

| Giriş Hat Sayısı: | 12 hat giriş |

| Tartım Sistemi: | Elektronik tartım |

| Tartım Hassasiyeti: | 0,1 gram |

| Tasnif sayısı: | 6 veya 7 boy |

| Operasyon: | 15″LCD ekran ile kolay kullanım |

| Analiz: | Yumurta adetleri ve ortalama ağırlık |

| Güç tüketimi: | 6,0 kW + (5×1,2 kW) = 12 kWh, 380VAC (5 adet otomatik toplama ile) |

| Ağırlık(Net/Brüt): | 5.800 kg./ 6.500 kg. |

DX600 Yerleşim Planı ve ölçüleri